Modbury sewer replacement

The situation

In Modbury, our sewerage system is showing its age and is in need of upgrading. We’re busy repairing, replacing and enlarging a lot of the sewers to help increase their capacity and efficiency. This essential work will also help reduce the risk of spills and pollutions from these assets.

Last year we took the difficult decision to postpone the planned sewer renewals in Modbury due to circumstances beyond our control.

The plan for Modbury

Since then, we’ve been redesigning the scheme and with our new contractor to reduce the impact it will have on the town. We’re now planning to repair the sewer with very latest lining technology, which will reduce the number of excavations needed.

We’re now in a much better position to carry out the works, and we’re planning to start on 8 January 2024 with the intention to finish by the end of February.

What will we see?

In some areas, we'll still have to use more traditional excavation techniques due to the age and condition of the sewer. You’ll see diggers and our teams and contractors busy building a new manhole and checking the suspected voids in the road before they put the area back to how they found it.

In areas where we are repairing the sewers using lining technology, the repairs all happen inside the pipes, so you won’t actually see a lot after the lining is installed – in fact, it might look like we’re not doing anything! But, it’s all going on underground. While you’re walking on the pavement, a metre or so under your feet, robots are repairing the sewers!

We're really excited to use this technology for the first time in Modbury. Previously, lining wasn't an option because of the differing diameters of the pipework as it goes along. However, advances in lining material mean that there's now a lining technique that works and will secure Modbury's sewers well into the future.

Here's a bit more about how the lining process works:

Reducing our environmental impact

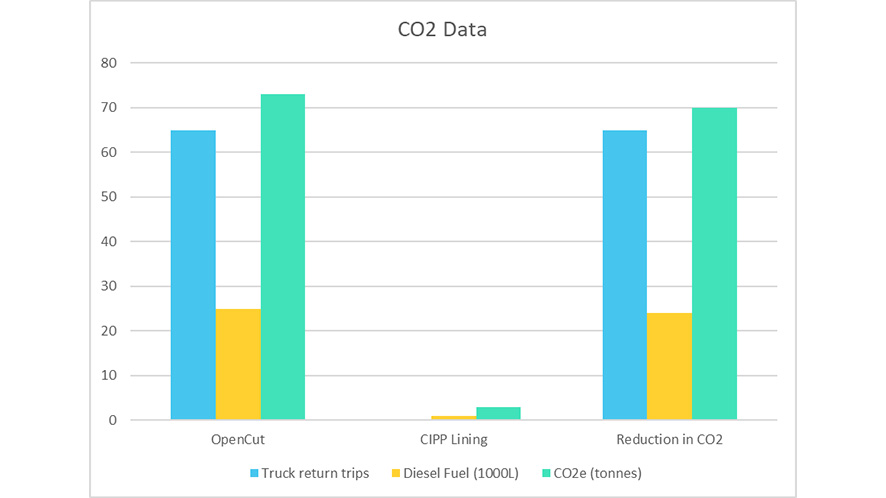

Transporting materials, and using diesel to power equipment are just some of the ways we emit carbon when doing repairs. Using the lining technology instead of traditional excavation, radically reduces the carbon emissions of our work.

This is just one of the ways we're protecting our environment, and working towards our NetZero goals.

What time will you be working?

We won’t start any noisy work until 8am – however, using the lining technique does mean we can’t guarantee daily end times. The lining needs to be cured and the connection from your properties have to be reopened before our teams leave the site, so that means, depending on the length of the pipe they’re working on that day, they could finish early or much later into the evening.

Will there be road closures?

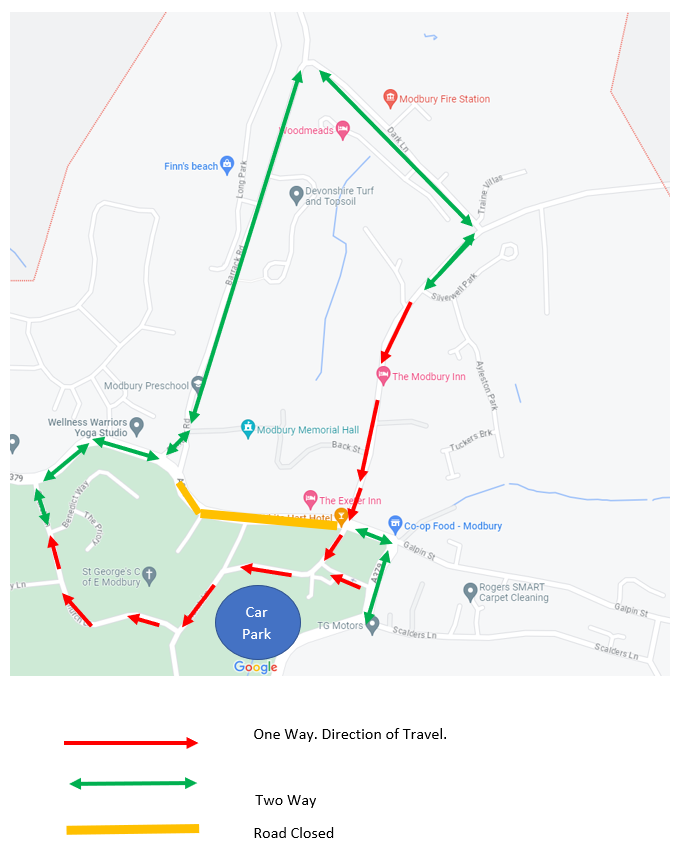

One of the most positive outcomes of using the lining technique, is that there is less need for road closures, although some will still be needed to keep our teams safe. These include:

- Broad Street: 8 January 2 weeks – Lane closure and traffic lights

- Church Street: 8 January 5 weeks - Road closure

- Moon Lane/Church Lane: 12 February 5 Days – Road closure

There will also be overnight road closures in some areas. We are working in these areas at night to minimise further disruption to the town and to maintain access to the health centre during the day.

- New Road: 19 January 1 day - Overnight road closure

- Poundwell Street: 8 January 1 week, and again 29 January 1 week - Overnight road closures

A diversion route will be in place with additional traffic management in Modbury to allow local access. All efforts will be made to minimise disruption and to maintain access to properties affected by the road closure, with all pavements and car parks remaining open.

Update August 2024:

We still have to complete two linings along Poundwell Street and Church Street which were delayed due to weather conditions. We hope to complete both linings at the same time, to minimise any further disruption. We didn’t want to come back during the busy Spring and Summer months because of the disruption this would have caused. Therefore, we plan to complete this work between 16-24 September.

During that week, there will be traffic lights on Church Street to keep our teams and you safe. We are also planning overnight closures on Monday 16 September on Back Street and Tuesday 17 September on Poundwell Lane. Please note that this work is weather dependant, so these dates may change nearer the time.